plug flow reactor design

The plug flow reactor model PFR sometimes called continuous tubular reactor CTR is normally the name given to a model used in chemical engineering to describe chemical reactions in continuous flowing systems of cylindrical geometry. In a plug flow reactor nutrients and sometimes organisms are introduced to the reactor continuously and move through the reactor as a plug.

The system may be either contained as in a water main oil pipeline or blood vessel or open as in a.

. Plug Flow Reactor Example. Reactant concentration changes in these two reactors are also compared based on their design equations to verify this. It is good to double check that we get the right steady state behavior.

Plug Flow Reactor PFR The third general type of reactor is the Plug Flow Reactor PFR. If you are author or own the copyright of this book please report to us by using this DMCA report form. Three different models the tanks-in-series model without interaction compartmental model the tank-in-series model with backflow and the dispersion model have been used in the literature to interpret RTD.

This type of continuous flow reactors are simple in design and practically has no power requirement. You can see that the steady state behavior is reached at approximately 10 time units which is the space time of the reactor in this example. Plug-flow of liquid 5.

A completed case has been pre. DC d r C Ideal batch. For batch reactors conversion is a function of time whereas for flow reactors at steady state it is a.

Reactat product Figure 5-1. Average pressure of reactor 20265kPa. Up to 24 cash back Plug Flow Reactors PFR In Plug flow reactor reactant continually flows through a cylindrical vessel or pipe.

Gaseous reactant is limiting 2. The PFR model is used to predict the behavior of chemical reactors of such design so that key reactor variables such as the dimensions of the reactor can be estimated. The reactor itself may consist of an empty.

Average temperature of reactor 2465oC. Plug flow reactor design pdf Page 3 of 6 ao Adham K Harris C Kokourine A 2017 Modeling and Process Features of Plug Flow Reactor with Internal Recirculation for Biomass A novel reactor combining the advantages of the MODAR reactor horizontal stirred reactor dynamic gas seal wall reactor and cool wall reactor was designed. Liquid is nonvolatile 7.

DC dt r C Position in a PFR is equivalent to time in a batch reactor x C. Examples of real reactors that approximate the flow pattern of ideal reactors are shown in Figure 10. Although there are many commonly used PATs 79 90 herein we only briefly discuss the ReactIR and focused beam reflectance measurement FBRM which could be used in continuous reactors.

Finite gas-liquid liquid-solid and intraparticle gradients Key Assumptions. So heat removal through jacket is major work in reactor design. Catalyst concentration is constant 8.

Add steady state solution. Most reactors used in industry approximate the ideal batch reactor PFR or CSTR. Otherwise Ignition can happen.

Design of Ideal Reactors Plug-flow reactor PFR A plug-flow reactor PFR may be used for both liquid-phase and gas-phase reactions and for both laboratory-scale investigations of kinetics and large-scale production. The reaction occurs along the flow path. The reaction is highly exothermic.

Debasree Ghosh Lecture notes on Polymer Reaction Engineering Module II. The reactor is designed in such a way that heat can be removed from the catalyst. Reactors with P e 100 present an ideal plug flow behaviour while reactors with P e 1 present an ideal perfectly mixed state.

Chemical Reaction Engineering CRE deals with the design of Chemical Reactors to produce chemicals. Plug Flow Reactor Detailed Cooling Jacket Design - posted in Industrial Professionals. Plug flow reactor design.

Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor. This research design of flow reactors Plug Flow Reactors and Continuous Stirred Tank Reactor for production of Dimethyl Ether from Dehydration of Methanol using the Alumina as Catalyst is an activity of chemical engineering which uses information knowledge and experience from a variety of areas which. Plug Flow Reactors PFRs Type of Reactor.

During the reactor design process it is important to consider the PATs that will be incorporated into the system eg design ports for suitable PATs. The reactant diminished along the length and there is no radial variation in concentration. Concentration changes with length down the reactor.

Mole of components mole CH3OH CH2O H2O N2 O2 12815929kmolhr. The plug flow reactor model PFR sometimes called continuous tubular reactor CTR or piston flow reactors is a model used to describe chemical reactions in continuous flowing systems of cylindrical geometry. The PFR model is used to predict the behaviour of chemical reactors of tubular design so that key reactor.

Continuously Stirred Tank Reactor CSTR Arranged as one long reactor or many short reactors in a tube bank. The design of Chemical Reactors is based on a few. Reaction rate constant for main and side reactions K1 and K2.

We specialize in Loop Reactors for gasliquid reactions as well as Stirred Tank Reactors and Plug Flow reactors for other types of reactions. Constant gas-phase concentration 4. In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR.

Reactor Design Andrew Rosen May 11 2014 Contents. HHT offers all aspects of Chemical Reactor Technology from chemistry consulting through detailed reactor and plant design to the delivery installation and commissioning of equipment. The same example problem has been worked in Aspen and Matlab.

This document was uploaded by user and they confirmed that they have the permission to share it. Reactor conversion 874. In fact real reactors can be modeled as networks or combinations of multiple plug-flow and stirred-tank reactors Towler and Sinnott 2013.

Kinds of Phases Present. First-order reaction wrt dissolved gas 3. This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above.

Gas Limiting and Plug-Flow of Liquid 1. Density of silver catalyst used 950kgm3. The phrase plug flow profile indicates that there is uniform velocity with no radial variation but.

Download Calculation Of Plug Flow Reactor Design. No radial variation in reaction rate concentration. Plug flow reactors and perfectly-mixed flow reactors are compared in the former chapter and the conclusion is that plug-flow reactors are usually advantageous over perfectly-mixed flow reactors for normal reaction kinetics.

We can solve the steady state plug flow reactor problem like this. Compare ideal batch and ideal PFR mass balances.

%20Plug-Flow-Reactor-Static-Mixer.jpg)

Polymerization Plug Flow Reactors For Viscous Processing Stamixco Static Mixer Products Technology

Plug Flow Reactor Vapourtec Ltd

Schematic Presentation Of The Plug Flow Reactor 1 Feed Preparation Download Scientific Diagram

Tubular Reactor The Ultimate Faq Guide Filson Filter

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Plug Flow Reactor Design Equation Youtube

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

1 4 Continuous Flow Reactors Elements Of Chemical Reaction Engineering Mole Balances Informit

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect

Plug Flow Reactor With Ramped Flowrate Modelled As A Series Of Download Scientific Diagram

Chapter 9 Professional Reference Shelf

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

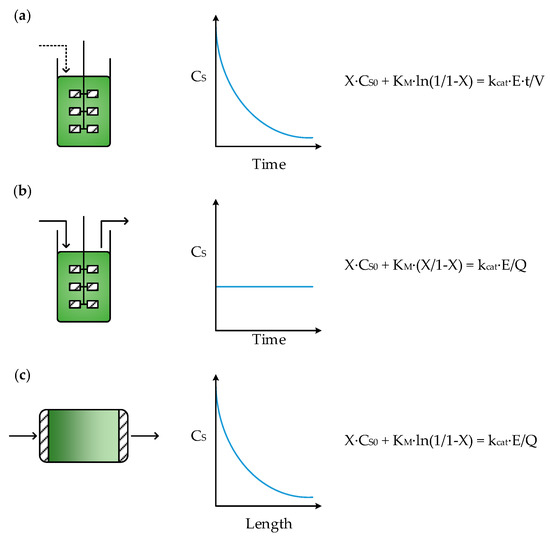

Catalysts Free Full Text Reactor Selection For Effective Continuous Biocatalytic Production Of Pharmaceuticals Html

Plug Flow Reactor An Overview Sciencedirect Topics

Continuous Stirred Tank Reactors Flow Technology

One Dimensional Pseudo Homogeneous Plug Flow Reactor Model Download Scientific Diagram

Deviation From An Ideal Flow Pattern Part 1 Petroleum Refining